The Short Answer: The size of your wood panels directly affects both the appearance and performance of your wood wall project, whether you're installing interior paneling or exterior siding. While many homeowners request wider planks for aesthetic reasons, narrower panels often offer better stability, easier installation, and a more consistent look.

Selecting the right panel size ranks among the most important decisions you'll make when planning a wood paneling or siding project. Whether you're creating a feature wall indoors or updating your home's exterior, the width and thickness of your panels will shape the final outcome.

Understanding Wood Panel Dimensions

Wood paneling comes in various sizes, and understanding the terminology helps you choose the best option for your project. Panel size typically refers to three measurements: width, length, and thickness. Each dimension plays a role in how your wall panels look and perform over time, indoors and out.

Common Panel Width Options

Panel width varies significantly across different products and wood types. Here's what you'll typically find on the market:

-

Narrow planks (3-5 inches): Traditional look, easy handling, less prone to warping

-

Medium planks (5-7 inches): Balanced appearance and stability

-

Wide planks (8-10 inches): Modern look with more cupping risk

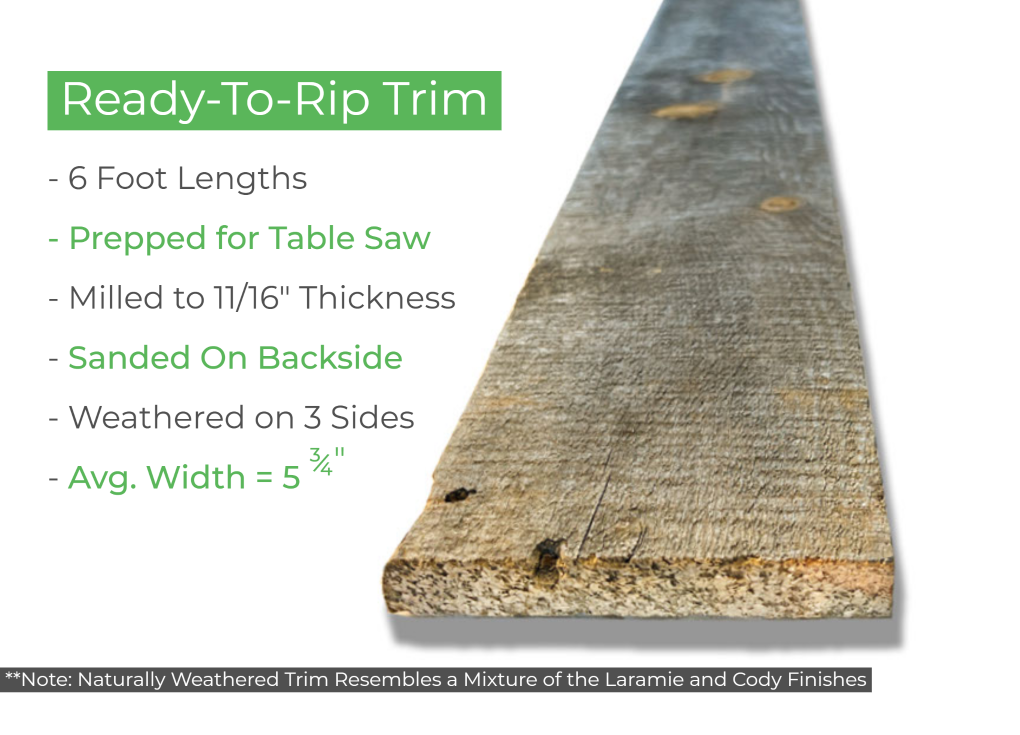

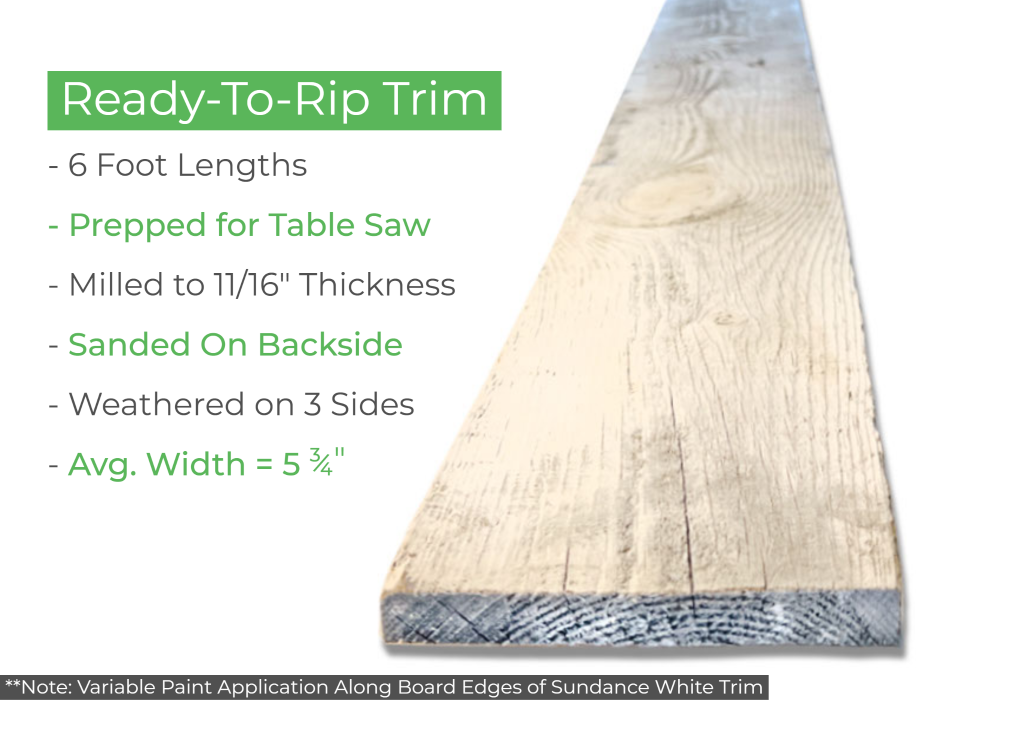

Panel Thickness Considerations

Panel thickness affects both durability and installation methods. Thicker panels offer more substance but require appropriate fastening. Most interior wall paneling ranges from 1/4 inch to 3/4 inch thick, while exterior siding typically requires greater thickness to withstand weather exposure. Your choice depends on whether you're creating a lighter application for accent walls or need the durability required for outdoor use.

Wide vs. Narrow Planks

Wider planks are a common request. Most people assume they'll create a more impressive look.

The Cupping Problem

Wide wood panels have a natural tendency to cup over time. Cupping occurs when the edges of a board curve upward or downward, creating a concave or convex surface. This happens because wider boards experience more uneven moisture distribution across their surface.

This problem affects both interior paneling and exterior siding, though outdoor applications face additional stress from weather exposure and temperature fluctuations. When panels start to cup, you face several problems:

-

Gaps appear between boards: The curving edges pull away from adjacent panels, creating visible openings in your wall or siding.

-

Fasteners become stressed: Nails and screws fight against the wood's movement, potentially loosening over time.

-

The professional finish deteriorates: What started as a beautiful installation begins looking uneven and poorly maintained.

Narrower planks resist cupping much more effectively. With less surface area, they maintain a flat, consistent appearance throughout their lifespan, which is critical for both interior aesthetics and exterior weather protection.