When it comes to wood, finishes matter. They serve two vital functions: 1. protecting the wood, and 2. improving its appearance. The finishing touch can make all the difference in a project, be it an accent wall or window trim.

So, what exactly are wood finishes? Put simply, they're substances you apply to wood for protection and aesthetics. They can provide a tough shield against damage and enhance the wood's natural features. From coffee tables to fences, a good finish is key to the durability and look of any wood piece.

The Short Answer: It's pretty straightforward – wood finishes come in two types: penetrating and surface. Penetrating finishes, like linseed or tung oil, soak into the wood providing protection from the inside out. Surface finishes, such as varnish, lacquer, or paint, create a protective layer on top of the wood. The right finish depends on the type of wood and its intended use.

Why Is Finishing Wood Recommended?

Better Durability

Finishing is essential for manufactured wood to protect it from wear and tear, moisture, and environmental damage. Manufactured wood often lacks the natural resilience of reclaimed or weathered wood, so applying a wood finish creates a necessary protective layer. This helps seal the surface, preserving the wood grain and enhancing its appearance while preventing cracking, warping, and discoloration. This is why applying a finish is always the final stage of any wood manufacturing process.

Minimizing the Risk of Water Damage

Finishing also helps guard the wood against exposure to elements like water, which can lead to swelling or rotting in untreated, manufactured wood. Whether it's wood furniture or hardwood floors, a water-resistant finish like water-based polyurethane or a durable finish like tung oil is crucial for maintaining the integrity and longevity of these pieces. Different finishes, from oil-based stains to water-based finishes, can also enhance the color and texture, highlighting the natural beauty of the wood surface.

Be Aware of Volatile Organic Compounds

Additionally, certain wood finishes, particularly solvent-based ones, can contain volatile organic compounds (VOCs). These compounds can release harmful chemicals into the air during application and drying, which is why many people are opting for low-VOC or water-based finishes to minimize environmental and health impacts.

Types of Wood Finishes: Penetrating Wood Finishes

Moving onto the first category of wood finishes – penetrating finishes. Penetrating wood finishes work in a pretty unique way. They are absorbed into the wood fibers, where they harden to strengthen and protect its core. It's like fortifying your wood from the inside, boosting its resistance to damage.

One feature of penetrating finishes is that they don't alter the look of the wood very much. Instead, they bring out the depth and texture of the wood grain, bringing back its richness and vibrance. This means that your wooden furniture or hardwood floors restore some of their natural charm.

Now, let's get specific with different types of penetrating finishes:

-

Tung Oil: Derived from the Tung tree seeds, this oil is a popular choice for a penetrating finish. It gives off a warm, hand-rubbed look and is resistant to water, alcohol, and food acids. However, tung oil takes longer to dry and requires more coats for significant protection.

-

Linseed Oil: Linseed oil, derived from flax seeds, creates a glossy finish with good grain enhancement. However, it isn't particularly durable and tends to darken over time. Also, it’s vital to remember that rags used with linseed oil can spontaneously combust if improperly stored.

-

Danish Oil: This is essentially a mixture of tung or linseed oil combined with varnish for extra durability. It offers good protection and enhances wood grain but can darken the wood slightly. Remember to use a clean cloth and apply in a well-ventilated area.

-

Cedar Oil: Designed for use on cedar wood, it helps enhance the natural oils and preserve the wood. However, it is somewhat susceptible to UV damage, so it's less suitable for outdoor furniture.

As you see, each type of penetrating wood finish has its unique strengths and drawbacks. The final selection narrows down to the kind of wood, your preference of appearance, the strain the wood would be subjected to, and of course, your personal preference. In our next section, we will explore their more common counterpart – surface wood finishes.

Types of Wood Finishes: Surface Wood Finishes

Shifting our attention now to surface finishes. Unlike penetrating finishes which soak into the wood, surface finishes sit on top of the wood. They provide a protective layer that guards against wear and tear, moisture, and UV rays. Their distinctive protective qualities are particularly desirable for high-traffic areas like kitchen tables or hardwood floors.

In addition, surface finishes not only provide protection but can also significantly modify the appearance of the wood. They can add a glossy, satin, or flat finish, making the wood look darker or lighter depending on the type used.

Here's a quick rundown of the different surface finishes:

-

Shellac: A natural finish derived from the secretions of the Lac bug, Shellac gives a warm glow to the wood and is easy to apply. However, it doesn't stand up well to heat or alcohol and can turn cloudy if exposed to moisture.

-

Lacquer: Fast-drying and durable, lacquer imparts a high-gloss finish that's resistant to damage. But, it requires special spray equipment to apply and has potent fumes.

-

Varnish: Offering excellent protection against heat, solvents, and scratches, varnish can be satin, gloss, or semi-gloss. However, it can yellow over time and needs a prolonged drying period between coats.

-

Polyurethane: Extremely durable and available in gloss, semi-gloss, and satin finishes, Polyurethane is resistant to water, alcohol, and scratches. But it can be challenging to apply evenly.

-

Paint: Offering endless color options and providing good protection, paint is an easy-to-apply finish. It does, however, conceal the wood grain.

Each of these surface finishes has functional characteristics and aesthetic properties you'll want to consider. To choose the ideal one, consider the type of wood, its use, projected wear and tear, and, of course, your desired final appearance.

About Our Finishes at Centennial Woods

So, let's talk about how we do things at Centennial Woods.

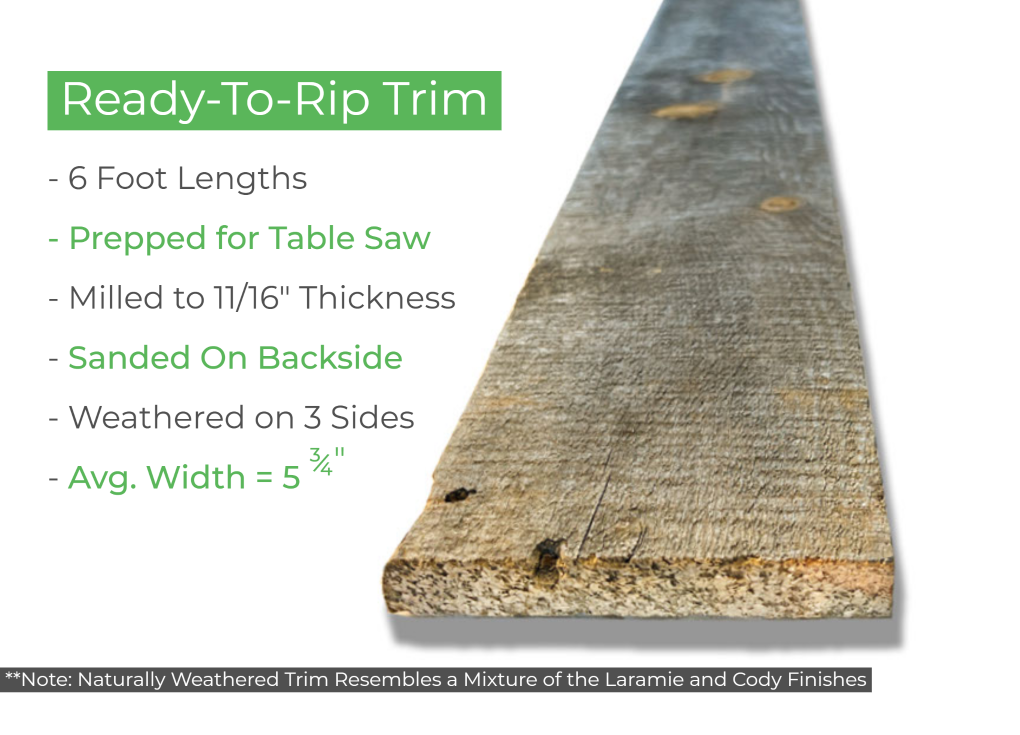

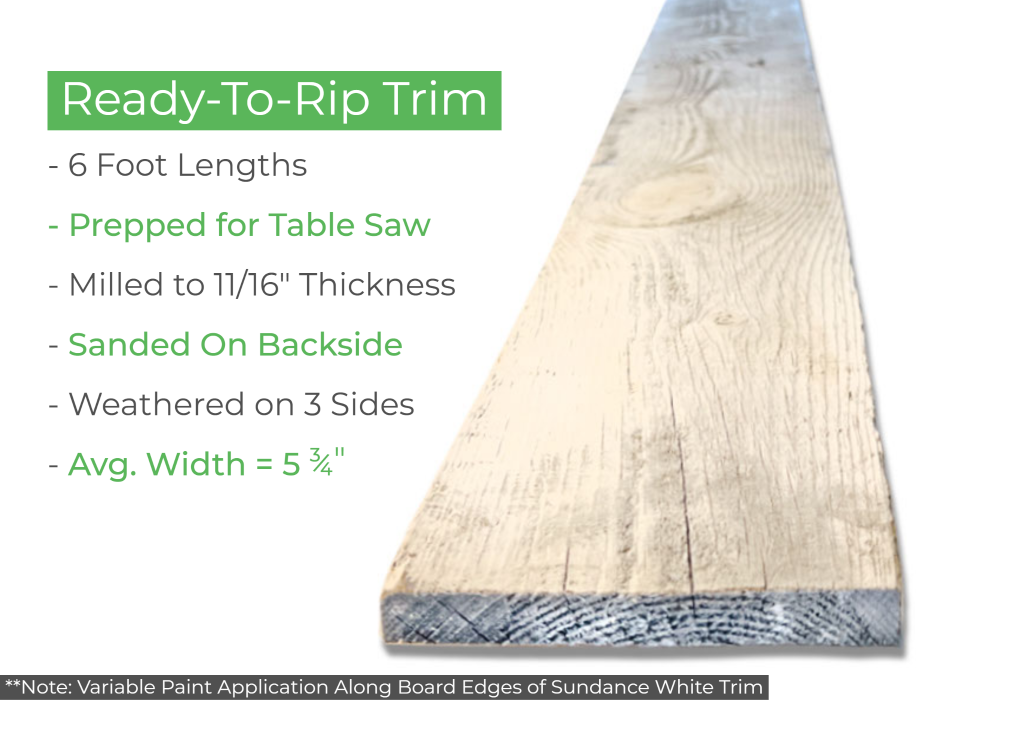

We believe in the raw beauty of nature and its ability to provide beauty beyond what man-made processes can deliver. That's why we repurpose weathered wood from Wyoming's snow fences. These fences have been naturally aged and weathered by the elements over time.